Product Category:

Product:

PVC Architectural Compound Materials Manufacturers

-

PVC Architectural Compound Materials

PVC Transparent Mesh Fabric

Unlimited use outdoors, for example as an advertising space, for wall and ceiling coverings, etc. Ve...

see more

-

PVC Architectural Compound Materials

Fire Retardant PVC Fabric

The fire retardant PVC fabric is a kind of safety net mainly used for the external wall of construct...

see more

-

PVC Architectural Compound Materials

PVC Architectural Membrane Materials

Our PVC architectural membrane materials with different thicknesses and translucency to match any pr...

see more

-

PVC Architectural Compound Materials

PVC Architectural Tent Fabric

Basic performance requirements of PVC architectural tent fabric Considering the various uses of tarp...

see more

-

PVC Architectural Compound Materials

PVC Architectural Tarpaulin Fabric

What are the characteristics and precautions of PVC architectural tarpaulin fabric? The general requ...

see more

-

PVC Architectural Compound Materials

PVC Ceiling Film

PVC ceiling film is a special PVC and an interior decoration material. One of the common types of ce...

see more

ONE STOP PROCUREMENT SERVICE

providing creative solution from concept to production to distribution.

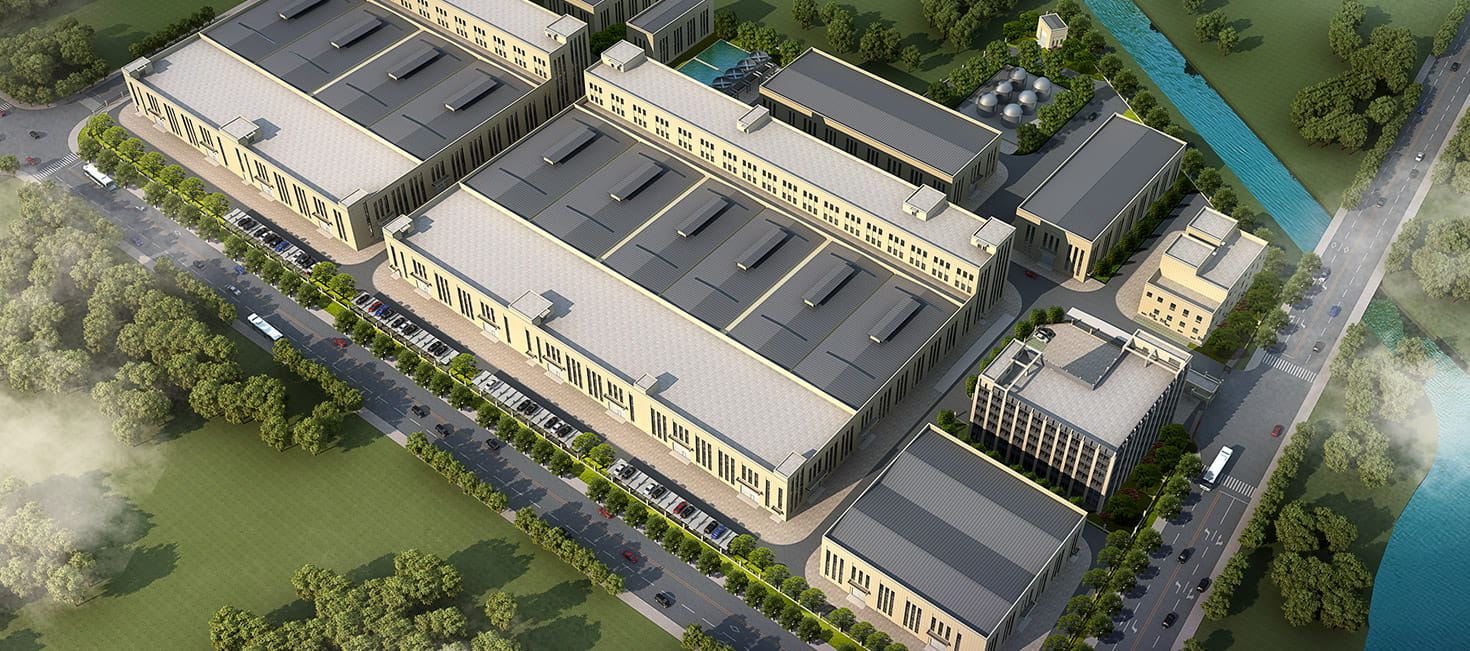

Contact UsWith a registered capital of 139 million CNY, MSD is a high-tech enterprise integrating R&D, production and sales of high-end PVC products and decorative film materials, being founded in 2002 and located in Maqiao Warp knitting Park, Haining city, Zhejiang Province.

MSD as a professional China PVC Architectural Compound Materials Manufacturers and OEM/ODM PVC Architectural Compound Materials Factory, we provide customers with Wholesale PVC Architectural Compound Materials for sale at a great price. Our products are under strict quality control throughout the manufacturing process.

MSD is specializing in the production of environmental friendly decorative materials, functional motion materials, flexible materials ect. The company owns the core technology which makes it to be the leading enterprise in PVC calendering coating industry.

At present, the company has 1100 employees, including 120 technicians, and a factory area of 180,000 square meters. In 2021, the sales has reached 2.6 billion CNY.

Follow us at @shanghaimsd.com

Are there specialized applications or industries that require specific properties or features in PVC tarpaulin fabric?

How is PVC tarpaulin fabric constructed and what are its key components?

What maintenance procedures are required to keep the PVC roll material in good condition?

Is PVC roll material easy to clean, and what cleaning agents or methods are recommended?

English

English русский

русский Français

Français Español

Español عربى

عربى