The 4011 translucent film also called white light-transmitting soft film. It is one of the soft film ceiling series, and it has the characteristics of nice light transmission and shadowless lighting. It has been widely used in office places, which is energy-saving and environmentally friendly. The white light-transmitting film also has some other advantages, such as mildew resistance, spray painting and so on. 4011 translucent film could replace the original interior light cloth with cheap price. It is easy to install.

Main Features

- The light transmittance is about 19-24%.

- The elongation rate is about 17%

- Good ink absorption and coloring

- Good perspective, clear and realistic picture, high degree of restoration

Application

- Indoor

- Printing (advertising)

- Decoration (building materials)

Advantages of MSD

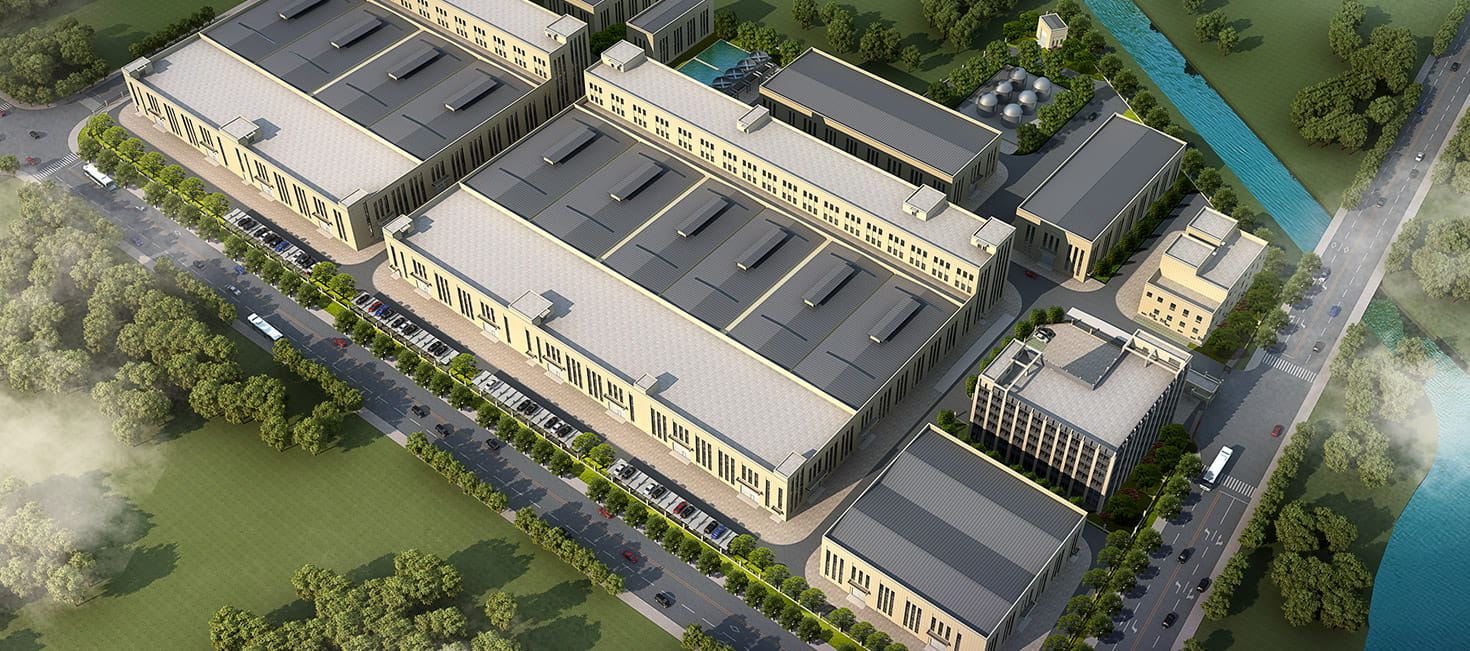

- One-stop production, the company with complete supporting facilities in the whole industrial chain in the world.

- Equipment: with the largest quantity of production equipment in the industry. MSD owns more than 20 rolling lines, more than 19 coating lines, and with 6 rolls, etc. Our equipment is self-summarized and designed after years of industry experience, which is more suitable for high-quality stability and high-yield efficiency.

- Technology: The fastest technical research and market development of domestic software films; so far it has not been surpassed in terms of sales volume,market share and product stability.

English

English русский

русский Français

Français Español

Español عربى

عربى